In the competitive footwear landscape, private label products are gaining traction. The global sneaker market was valued at approximately $79 billion in 2021. This figure is expected to grow, driven by increasing consumer demand for personalized and unique products. Private label sneaker manufacturers play a crucial role in this trend.

These manufacturers offer retailers the ability to create customized brands. Many brands opt for private labels to differentiate from mainstream offerings. For instance, a study showed that nearly 60% of shoppers prefer private label brands for their unique styles. However, challenges persist. The quality control for private label sneakers can sometimes be inconsistent. Retailers need to ensure suppliers meet high standards.

In exploring the top private label sneaker manufacturers, businesses must consider factors such as quality, scalability, and production capabilities. This insight is vital for making informed decisions. Finding the right private label sneaker manufacturer can significantly impact a brand's success in the bustling sneaker market.

Private label sneakers have become a notable segment in the footwear market. These products are made by manufacturers but sold under a retailer's brand. This allows businesses to offer unique designs at competitive prices. The appeal of private label sneakers lies in customization. Brands can tailor styles to fit their audience. Often, this leads to a strong connection with customers.

Market trends show a growing demand for these sneakers. Retailers see opportunities to innovate. Some focus on sustainability, using eco-friendly materials. Others cater to niche markets, like athletic enthusiasts. However, the challenge lies in maintaining quality. Poor craftsmanship can damage a brand’s reputation. Additionally, rapid production timelines can lead to errors.

Balancing cost and quality is essential. Brands must be cautious in their partnerships with manufacturers. Not all suppliers meet the necessary standards. Researching potential manufacturers is vital. Businesses should seek out reliable ones that prioritize quality control. In the end, understanding one’s target audience is key. This insight drives the success of private label sneakers in an ever-evolving market.

When selecting the best private label sneaker manufacturers, consider quality, design, and production capabilities. Quality is key. It affects customer satisfaction and brand reputation. Look for manufacturers with a strong track record. They should deliver consistently high-grade products.

Design is equally important. A unique design can set your sneakers apart from competitors. Discuss your vision clearly with potential manufacturers. They should be open to collaboration and creative input.

Tips: Ask for samples to assess comfort and durability. Visit their factories, if possible, to see processes firsthand. A factory visit can reveal a lot about their operation.

Lastly, think about production capacity. Ensure the manufacturer can meet your demands. They should handle large orders without sacrificing quality. Consider their lead times, too. Long delays can hurt your market launch. Balancing these factors is crucial for success.

Navigating the world of private label sneakers offers unique opportunities. Many manufacturers have diverse capabilities that can cater to different market needs. These companies often focus on quality, customizing designs, and meeting specific customer demands. Their ability to provide private label options can significantly enhance retail collections without investing in brand development.

Some manufacturers excel in material sourcing. They understand the importance of using high-quality fabrics and components. This expertise can lead to durable and stylish footwear. Others may focus on quick production times, allowing brands to respond swiftly to trends. However, not all manufacturers can maintain consistent quality during rapid production runs. Brands must evaluate their supply chain carefully to avoid quality dips.

Innovation is a key driver in this sector. Many manufacturers are exploring sustainable materials and ethical production practices. This shift reflects changing consumer demands for eco-friendly options. Yet, some manufacturers struggle to balance innovation with affordability. Brands should remain cautious and conduct thorough research before partnering, ensuring they align with their values and goals.

When exploring the landscape of private label sneaker brands, one can observe significant differences in quality and design. Manufacturers often differ in their sourcing of materials. Some prioritize eco-friendly fabrics, while others opt for cost-effective synthetic options. This choice greatly influences the final product. Additionally, the production techniques can vary. Some use advanced technologies for precision, while others rely on traditional methods that may lack consistency.

Customer feedback highlights the importance of branding as well. A brand’s story can affect consumer perception. A compelling narrative draws buyers in, enhancing loyalty. However, not every brand manages this well. Some appear generic or lack distinctiveness. This often leads to challenges in standing out in a saturated market.

Price points also play a crucial role. While some brands offer premium pricing for perceived quality, others compete with value-based pricing to attract budget-conscious consumers. This disparity can create confusion. Shoppers might question if higher prices guarantee better craftsmanship. In this quest for differentiation, some brands miss key opportunities to refine their offerings and resonate with their target audience. It is an ongoing challenge in the private label sneaker industry.

| Manufacturer Rank | Annual Production Capacity (Pairs) | Main Production Material | Specialization Areas | Country of Operation |

|---|---|---|---|---|

| 1 | 1,500,000 | Synthetic Leather | Athletic & Casual Sneakers | Vietnam |

| 2 | 2,000,000 | Canvas | Fashion & High-Performance | China |

| 3 | 1,000,000 | Recycled Materials | Eco-friendly Sneakers | Indonesia |

| 4 | 800,000 | Mesh | Running & Sports Footwear | Cambodia |

| 5 | 600,000 | Nubuck Leather | Luxury Sneakers | Italy |

| 6 | 750,000 | Rubber | Casual Footwear | Brazil |

| 7 | 1,200,000 | Ethylene Vinyl Acetate | Children's Sneakers | Turkey |

| 8 | 950,000 | Leather | Classic Sneakers | Spain |

| 9 | 500,000 | Denim | Streetwear Sneakers | Mexico |

| 10 | 1,800,000 | Breathable Mesh | Sports and Outdoor | Thailand |

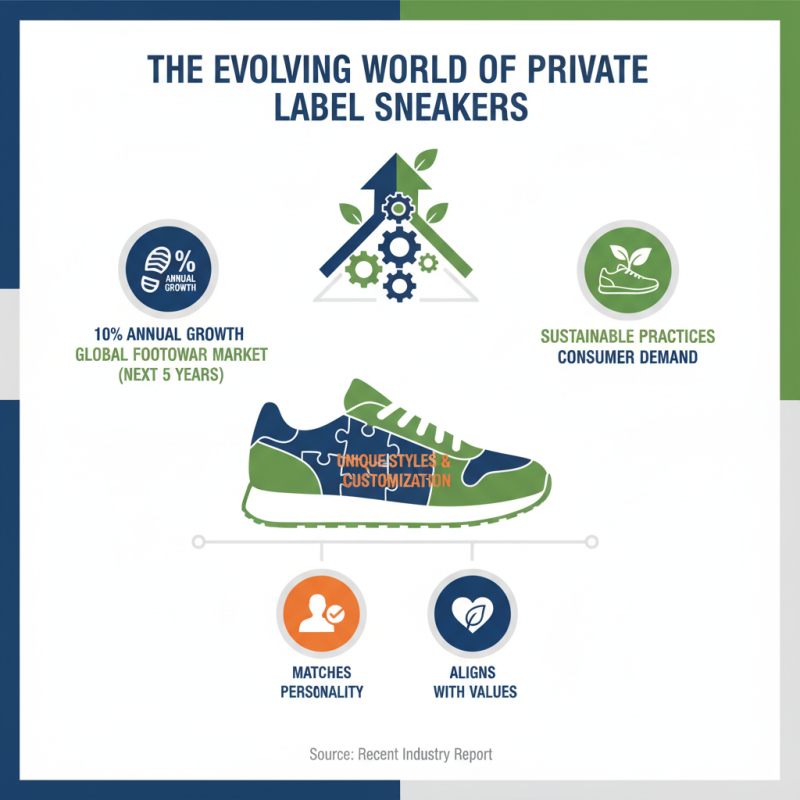

The private label sneaker sector continues to evolve, driven by consumer demand for unique styles and sustainable practices. According to a recent report, the global market for private label footwear is expected to grow by 10% annually over the next five years. This growth reflects an increasing interest in customizable options. Consumers seek footwear that matches their personality and values.

Innovations in manufacturing technologies are changing the landscape. Automation and 3D printing enhance production efficiency. Yet, this also raises concerns about job displacement in traditional manufacturing roles. Brands must navigate this challenge carefully to maintain a balanced workforce. A strategic pivot towards eco-friendly materials is also vital. Research shows that 65% of consumers are willing to pay more for sustainable products.

Tip: Engaging with customers through personalized designs can boost loyalty. Inviting feedback during the design process may yield valuable insights. Consider collaborating with local artisans to add authenticity.

Challenges remain. Rapid changes can leave some brands struggling to keep up. Managing quality while ensuring sustainability can complicate operations. It's essential to strike a balance that appeals to modern consumers while maintaining ethical standards. The future of private label sneakers promises creativity and sustainability, but the road ahead requires thoughtful reflection.